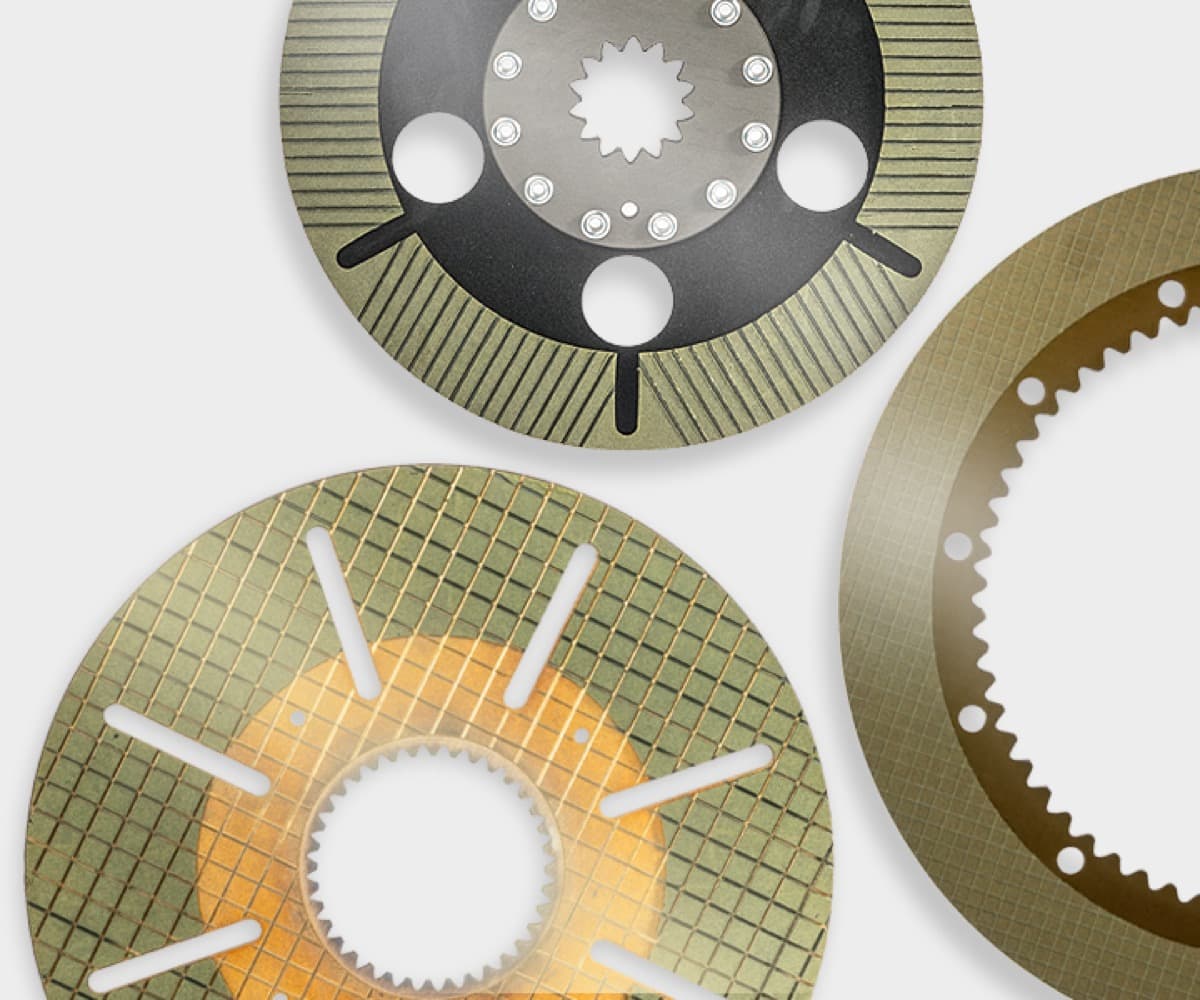

FMC are well aware that our products are used in applications where safety, performance and reliability are of prime concern. For this reason all our products are manufactured to the same specifications, with the same quality materials and workmanship as the Original Equipment Manufacturer (OEM).

Unless there are specific instructions provided by the OEM, in terms of hours of use, flatness, surface defects or wear, then the steel mating plates should always be replaced. Whilst on first inspection the plates might look acceptable to go back into a transmission or brake, you have no way of telling if the stresses the plate has been put under are close to causing the part to fail.

The steel plates are designed to work a set number of hours by the OEM, plus a safety margin. Thereafter the plate could suffer stress fractures of the teeth/lugs or even of the working surface. They could also become dished/coned and hence lead to premature failure of the rebuilt unit.

It’s very important especially for the paper and graphite friction materials that they are soaked for a minimum of 30 minutes in the transmission or brake fluid to be used in the application. Putting dry plates into an application can cause the surface of the friction material to be glazed or even burnt, leading to early failure.

Send us as much detail as possible, inside diameter, outside diameter, thickness, number of teeth/lugs, material, etc. We have a large database and in many cases we can identify the parts from minimal information.

The amount of wear allowed in a particular application will be laid down by the OEM and needs to be adhered too. That said it would be normal to design for an allowance of half of the groove depth.

At the development stage a lot of background work goes into achieving the optimum performance from a material and a particular oil. There can be a dramatic change in coefficient of friction if the oil as specified by OE is not used. As a general rule additives, particularly friction modifiers are to be avoided.

In order to provide a thorough evaluation, we would require all of the friction and steel discs to be returned and an oil analysis report from the used oil, as well as a detailed summary of the machine, serial number, hours worked and any additional information that you consider appropriate.

If you have a question that’s not answered on this page, please get in touch with a member of our team at FMC.

Contact usSign up to receive the latest FMC product news, exclusive offers and more.